Why Aluminum Busbars Are Transforming Power Distribution in Modern Industries

As the demand for more efficient, lightweight, and cost-effective electrical components continues to grow, aluminum busbars are becoming the preferred choice for engineers and manufacturers across a wide range of industries. At AP Precision Metals, we specialize in crafting high-performance aluminum busbars tailored to the evolving needs of modern power systems. Our precision-engineered products offer unparalleled value, performance, and sustainability for today’s energy-conscious world.

What Makes Aluminum Busbars a Game-Changer?

Aluminum busbars serve as conductive pathways that carry electrical current between power distribution points. Compared to traditional wiring systems, busbars provide a more efficient method of managing current flow in confined spaces while supporting higher load capacities. Their robust, flat design also allows for easier integration into complex systems such as electrical cabinets, control panels, and energy storage units.

While copper was historically the go-to material for busbars, aluminum has rapidly gained traction due to its multiple benefits. The shift toward aluminum busbars is not just a trend—it’s a strategic evolution driven by technical performance, material cost advantages, and environmental sustainability.

Top Benefits of Using Aluminum Busbars

1. Exceptional Cost Savings

One of the most compelling reasons for switching to aluminum is its lower material cost. Aluminum can be up to 60% less expensive than copper, making it ideal for large-scale applications where material costs can quickly add up. For organizations seeking to reduce capital expenditures without sacrificing quality, aluminum busbars offer a practical and economical solution.

2. Superior Weight-to-Conductivity Ratio

Aluminum is significantly lighter than copper—approximately one-third the weight for the same volume. Despite being less conductive per unit area, its favorable weight-to-conductivity ratio makes aluminum busbars perfect for systems that require both performance and reduced structural weight. This advantage is particularly valuable in aerospace, automotive, and renewable energy sectors.

3. Enhanced Corrosion Resistance

Modern aluminum alloys are designed to resist oxidation and corrosion, especially when treated with protective coatings or insulation. AP Precision Metals offers multiple finishing options to ensure long-term durability in both indoor and outdoor environments, including marine and industrial settings where corrosion protection is critical.

4. Flexibility in Design and Manufacturing

Aluminum busbars are easier to machine, bend, and stamp compared to copper. This allows for greater customization and faster production times. Our advanced CNC machining capabilities at AP Precision Metals ensure that every aluminum busbar meets tight tolerances and customer specifications, whether for a single prototype or high-volume production run.

5. Environmentally Friendly

Aluminum is 100% recyclable without losing its inherent properties. The recycling process consumes just 5% of the energy required to produce primary aluminum, making it one of the most sustainable metals available. Using aluminum busbars aligns with green initiatives and supports organizations working toward carbon neutrality.

Custom Busbar Solutions Designed for Performance

At AP Precision Metals, we understand that no two applications are the same. That’s why we offer fully customizable aluminum busbars to meet a wide array of performance requirements and physical constraints. Our capabilities include:

- Flat and extruded aluminum busbars for conventional and high-load applications

- Laminated busbars to reduce inductance and improve electrical performance

- Insulated busbars for added safety and system protection

- CNC-machined configurations for complex geometries and precise fitment

From consultation to prototyping and final production, our team works closely with you to develop solutions that maximize performance and minimize costs.

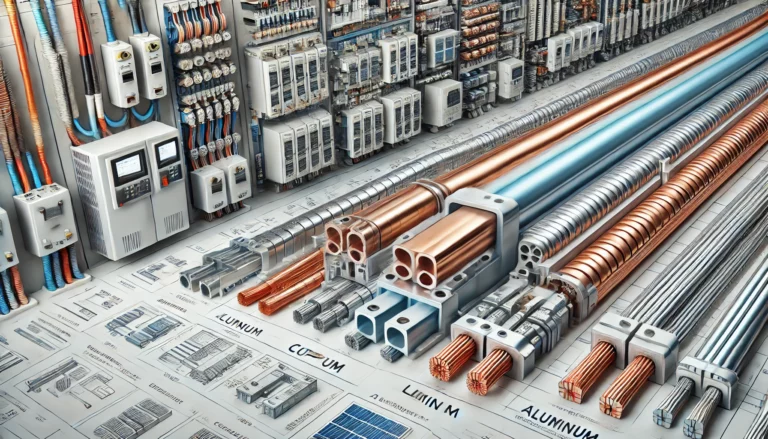

Where Aluminum Busbars Are Used

Aluminum busbars are extremely versatile and are used across industries where high current capacity, weight reduction, and space optimization are key. Common applications include:

- Renewable Energy Systems – Solar and wind energy installations use aluminum busbars for efficient energy transmission and thermal performance.

- Electric Vehicles (EVs) – Lightweight aluminum reduces vehicle weight while efficiently connecting battery modules and power electronics.

- Industrial Control Panels – Busbars simplify layouts and support high-load electrical systems in manufacturing facilities.

- Data Centers – High-efficiency power distribution is critical to maintaining uptime and energy efficiency in data center operations.

- Telecommunications – Equipment and infrastructure rely on durable, high-conductivity components to deliver uninterrupted power.

Innovative Manufacturing Backed by Precision

Our aluminum busbars are manufactured using state-of-the-art techniques that ensure maximum conductivity, structural integrity, and thermal performance. AP Precision Metals leverages cutting-edge processes such as:

Laser Welding

Laser welding enables high-precision joints that minimize resistance and maximize conductivity while maintaining structural strength. This is critical for compact or high-performance systems.

Cold Spray Technology

We incorporate cold spray processes to apply conductive coatings and surface reinforcements without melting the base material. This technique enhances the performance and corrosion resistance of aluminum busbars in demanding environments.

Automated Cutting and Stamping

Our automated systems provide unmatched consistency and speed, which is essential for scalable production and on-time delivery.

Advanced Insulation Techniques

We offer multiple insulation options including heat shrink, epoxy coatings, and laminated barriers that ensure compliance with safety standards and increase the service life of the busbar systems.

Designing with Efficiency in Mind

Designing an aluminum busbar system requires careful consideration of electrical, thermal, and mechanical factors. Our engineering team collaborates with clients to account for:

- Electrical Load Requirements – Ensuring that the cross-sectional area supports the necessary ampacity and voltage drop requirements

- Thermal Management – Managing heat dissipation through layout, spacing, and material treatments

- Mechanical Constraints – Designing for vibration, environmental conditions, and spatial limitations

- Connection Interfaces – Machining and finishing for seamless integration with terminals, power blocks, and external components

Our design-first approach ensures that your aluminum busbar systems are not only high-performing but also easy to install and maintain.

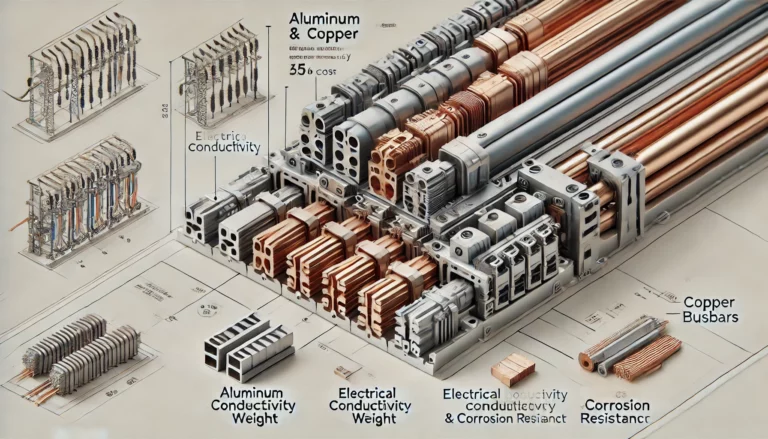

Aluminum vs. Copper Busbars: A Practical Comparison

While copper remains a strong material for electrical conductors, aluminum offers unique benefits that make it a superior choice in many applications. Here’s a quick comparison:

| Property | Aluminum Busbars | Copper Busbars |

|---|---|---|

| Cost | Lower | Higher |

| Weight | Lighter | Heavier |

| Conductivity (per unit weight) | Higher | Lower |

| Corrosion Resistance | Excellent (with treatment) | Good |

| Recyclability | 100% | 100% |

For many projects, the trade-offs between aluminum and copper favor aluminum when proper design, manufacturing, and material selection are considered—especially when partnered with an experienced manufacturer like AP Precision Metals.

Trust AP Precision Metals for Your Next Aluminum Busbar Project

At AP Precision Metals, we combine innovation, craftsmanship, and a customer-first approach to deliver aluminum busbars that meet the highest standards of performance and reliability. From design to delivery, our team is committed to helping you optimize your electrical systems with lightweight, cost-effective, and sustainable solutions.

Contact us today to learn more about how our aluminum busbar solutions can support your next project.