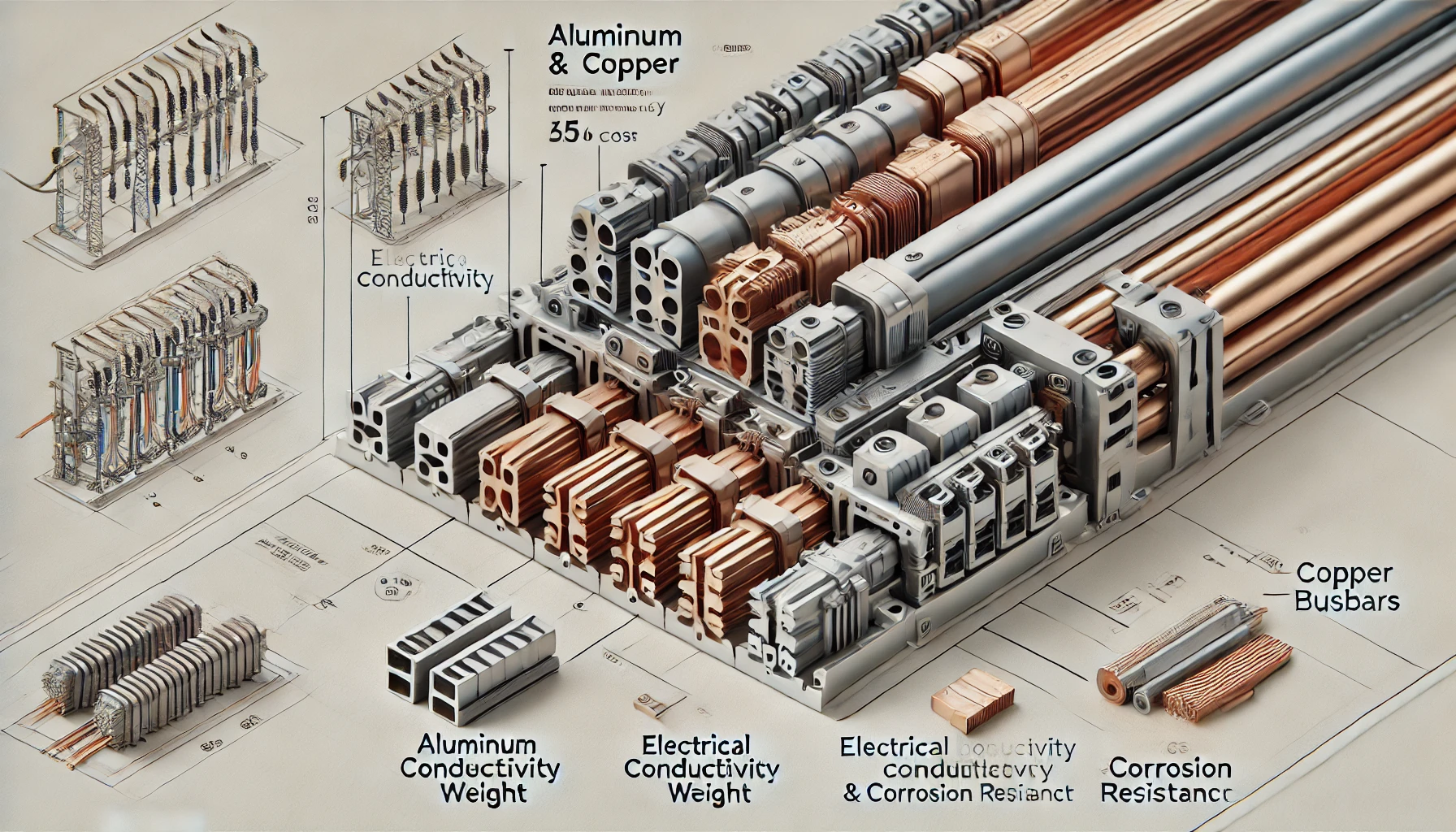

Aluminum Busbar vs Copper: Key Differences

When it comes to electrical conductors, the debate between aluminum busbar vs copper is ongoing. Both materials are widely used in various applications, but they each have their own unique properties and benefits. As a metal expert at AP Precision Metals, I’ll help you understand the key differences between aluminum busbars and copper busbars, so you can make an informed decision for your projects.

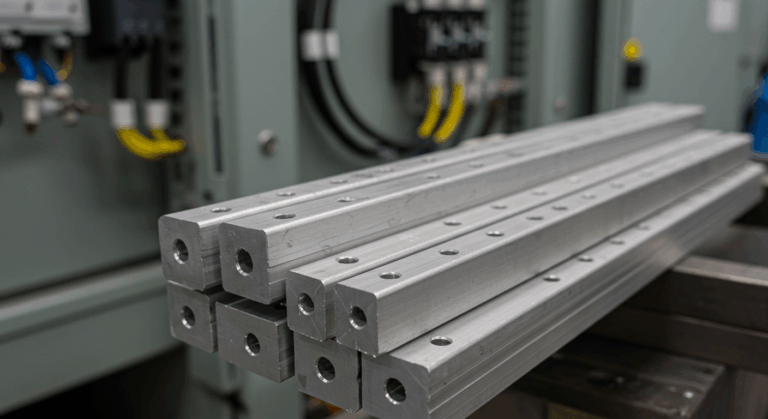

The Basics of Busbars

Busbars are crucial components in electrical power distribution systems, serving as the main conduits for electricity. They come in different shapes, sizes, and materials, with aluminum and copper being the most common choices. Their primary function is to conduct substantial electrical currents and distribute them to various circuits.

Electrical Conductivity

Copper is well-known for its excellent electrical conductivity. It has a conductivity rating of 100% IACS (International Annealed Copper Standard), making it the benchmark for comparing other conductive materials. This high conductivity means copper busbars can carry more current than aluminum busbars of the same size.

Aluminum, on the other hand, has a conductivity rating of approximately 61% IACS. While this is lower than copper, aluminum busbars compensate for this by being larger in size. When designed properly, aluminum busbars can match or even exceed the current-carrying capacity of copper busbars.

Weight and Density

One of the significant advantages of aluminum is its weight. Aluminum is about one-third the weight of copper, making aluminum busbars much lighter. This weight reduction can be beneficial in applications where weight is a critical factor, such as in aerospace, automotive, and portable devices. The lighter weight also simplifies handling and installation.

Copper busbars, being denser and heavier, may pose challenges in applications where weight is a concern. However, their robustness and durability often make up for this disadvantage, particularly in fixed installations where weight is less of an issue.

Cost Considerations

Cost is another important factor to consider when choosing between aluminum busbar vs copper. Generally, aluminum is less expensive than copper. The cost savings can be substantial, especially for large-scale projects. This price difference can make aluminum busbars a more attractive option for budget-conscious projects.

However, it’s essential to consider the total cost of ownership. Copper busbars, while more expensive initially, may offer longer service life and lower maintenance costs, which can offset the higher upfront investment.

Corrosion Resistance

Corrosion resistance is a critical consideration in environments where busbars are exposed to moisture or chemicals. Copper busbars have excellent resistance to corrosion, especially when properly treated or coated. This makes copper ideal for use in harsh or outdoor environments.

Aluminum, however, forms a protective oxide layer that prevents further oxidation and corrosion. While this provides good resistance, aluminum busbars may still require additional protection or coatings in particularly aggressive environments.

Thermal Expansion

Thermal expansion refers to the tendency of materials to expand when heated and contract when cooled. Aluminum has a higher coefficient of thermal expansion than copper, meaning it expands and contracts more with temperature changes. This can be a consideration in applications where temperature fluctuations are common, as it may require special design considerations to accommodate the expansion and contraction of aluminum busbars.

Copper busbars, with their lower coefficient of thermal expansion, are less susceptible to these temperature-induced size changes, making them more stable in varying thermal conditions.

Applications of Aluminum and Copper Busbars

Both aluminum and copper busbars have their unique applications, leveraging their specific advantages.

Aluminum Busbar Applications

- Aerospace and Automotive Industries: The lightweight nature of aluminum makes it ideal for applications where weight savings are crucial. Aluminum busbars are commonly used in aircraft and automotive electrical systems.

- Power Distribution Systems: Aluminum busbars are often used in power distribution systems where the cost is a significant factor. They provide an economical solution for distributing electricity over long distances.

- Portable Devices: The reduced weight of aluminum busbars makes them suitable for portable and mobile devices where weight and size are critical considerations.

Copper Busbar Applications

- Industrial Electrical Systems: Copper’s superior conductivity and durability make it the material of choice for industrial electrical systems, including switchgear, transformers, and substations.

- Marine and Offshore Environments: Copper’s excellent corrosion resistance is beneficial in marine and offshore environments, where exposure to moisture and salt is common.

- High-Reliability Applications: For applications requiring high reliability and minimal maintenance, such as hospitals and data centers, copper busbars provide a robust and dependable solution.

Making the Right Choice

Choosing between aluminum busbar vs copper depends on various factors, including the specific requirements of your application, budget constraints, and environmental conditions. Here’s a brief comparison to help you decide:

| Feature | Aluminum Busbar | Copper Busbar |

|---|---|---|

| Conductivity | Lower (61% IACS) | Higher (100% IACS) |

| Weight | Lighter (one-third the weight of copper) | Heavier |

| Cost | Lower initial cost | Higher initial cost |

| Corrosion Resistance | Good (forms protective oxide layer) | Excellent (especially when coated) |

| Thermal Expansion | Higher coefficient of thermal expansion | Lower coefficient of thermal expansion |

When deciding between aluminum busbar vs copper, it’s crucial to evaluate the specific needs of your project. Aluminum busbars are a cost-effective, lightweight solution suitable for various applications, especially where weight and budget are concerns. Meanwhile, copper busbars offer superior conductivity, durability, and reliability, making them ideal for high-performance and harsh environment applications. Understanding these key differences will help you select the right material, ensuring optimal performance and cost-efficiency for your electrical distribution needs.

In conclusion, both aluminum and copper busbars have their distinct advantages and are suited for different applications. By carefully considering the factors discussed above, you can make an informed decision that best meets your project’s requirements. Whether you prioritize cost, weight, conductivity, or durability, understanding the key differences between aluminum busbar vs copper will guide you in selecting the ideal busbar for your needs.