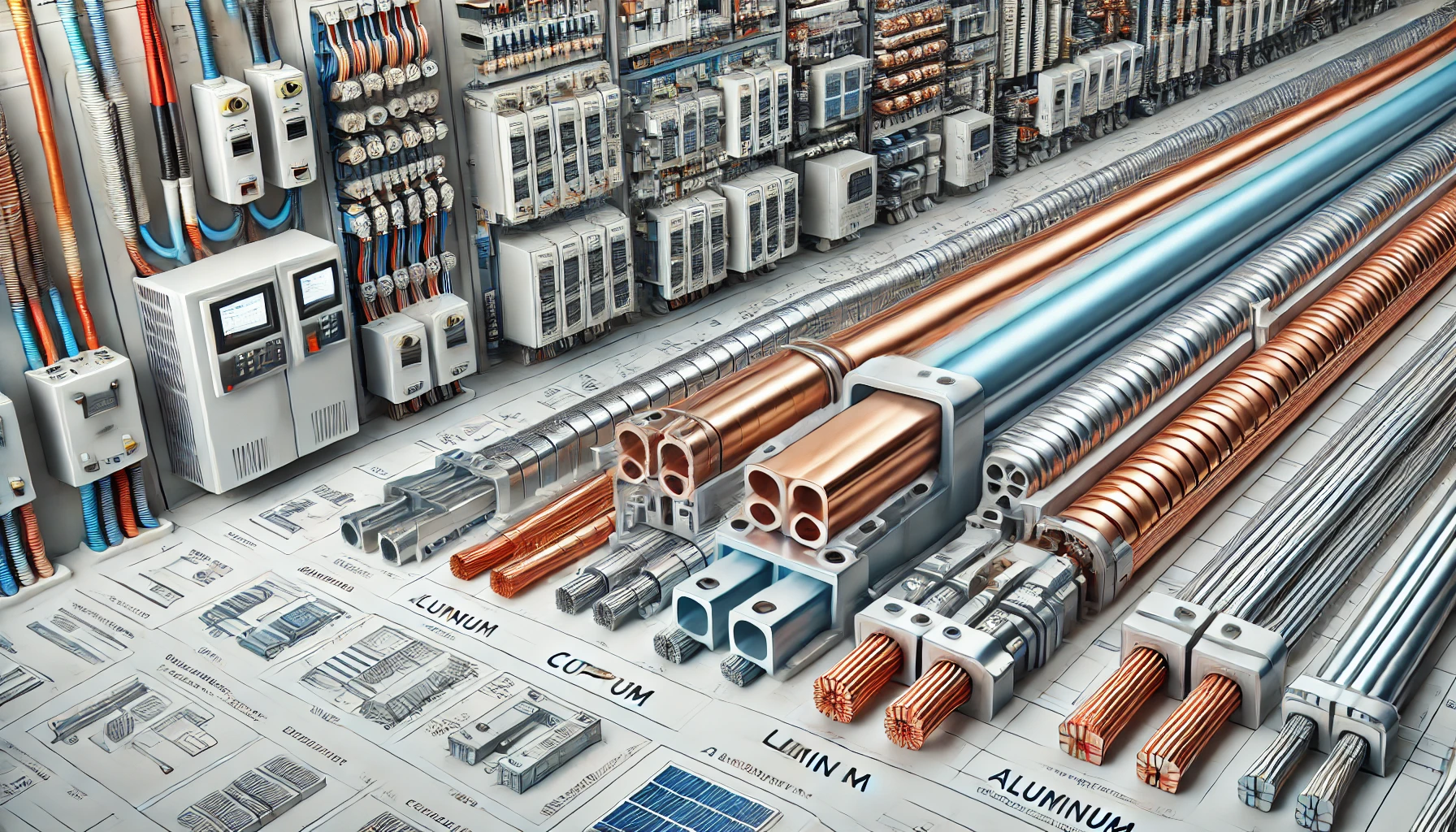

Aluminum and Copper Busbars | Efficient Electrical Conductors for Power Systems

When it comes to power distribution and electrical conductivity, aluminum and copper busbars are at the forefront of efficient and reliable solutions. As a critical component in electrical systems, busbars play a crucial role in ensuring the effective transmission and distribution of electric power. In this article, we will delve into the importance of aluminum and copper busbars, their advantages, applications, and why they are preferred in power systems.

What Are Busbars?

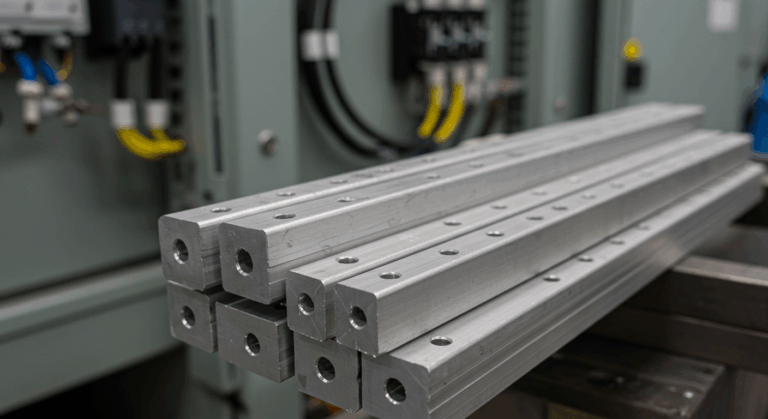

Busbars are metallic strips or bars used for conducting electricity within a switchboard, distribution board, substation, or other electrical apparatus. They are typically made from highly conductive materials like aluminum or copper, which enable them to carry large current loads efficiently.

Why Choose Aluminum and Copper Busbars?

Aluminum and copper are the two most commonly used materials for busbars due to their excellent electrical conductivity and other beneficial properties. Here, we’ll explore why these materials are favored:

Advantages of Copper Busbars

- High Conductivity: Copper busbars are known for their superior electrical conductivity. This means that they can carry more current than aluminum busbars of the same size.

- Durability: Copper is highly resistant to corrosion, which ensures a longer lifespan for busbars made from this material.

- Thermal Performance: Copper busbars can withstand higher temperatures, making them suitable for applications that involve high thermal loads.

- Mechanical Strength: Copper’s mechanical strength is higher than that of aluminum, providing greater durability and reliability.

Advantages of Aluminum Busbars

- Cost-Effective: Aluminum is more cost-effective than copper, making it a popular choice for large-scale electrical installations.

- Lightweight: Aluminum is significantly lighter than copper, which reduces the overall weight of the electrical installation and can ease the handling and installation process.

- Good Conductivity: While not as conductive as copper, aluminum still offers good electrical conductivity, especially when anodized.

- Corrosion Resistance: Anodized aluminum has a natural oxide layer that protects it from corrosion, similar to copper’s inherent resistance.

Applications of Aluminum and Copper Busbars

Busbars are used in various applications where the efficient and reliable transmission of electricity is essential. Here are some common applications:

- Power Distribution Systems: Both aluminum and copper busbars are widely used in power distribution systems to carry large currents across switchboards and distribution boards.

- Electrical Panels: They are a crucial component in electrical panels, providing a central point for electrical distribution.

- Industrial Settings: In industrial plants, busbars are used to distribute power to machinery and equipment.

- Renewable Energy Systems: Busbars play a key role in solar and wind energy systems, where they help in the efficient transmission of electricity generated from renewable sources.

- Data Centers: In data centers, busbars provide a reliable way to distribute power to servers and other critical infrastructure.

Critical Considerations for Choosing Busbars

When selecting between aluminum and copper busbars, several factors should be taken into account:

- Current-Carrying Capacity: Copper busbars can carry more current for a given size compared to aluminum, making them suitable for high-current applications.

- Cost: If budget constraints are a consideration, aluminum busbars can provide a more cost-effective solution without compromising too much on performance.

- Weight and Space: For installations where weight is a critical factor, aluminum busbars offer a significant advantage due to their lower density.

- Environment: In corrosive environments, copper’s superior corrosion resistance may provide longer-lasting performance.

- Thermal Management: For applications with high thermal loads, the superior thermal conductivity of copper busbars makes them a better choice.

The Future of Busbars: Innovations and Trends

As technology advances, so do the materials and techniques used in the manufacturing of busbars. Here are some trends and innovations to watch for:

- Hybrid Busbars: Combining the benefits of both copper and aluminum, hybrid busbars are being developed to provide a balanced solution that optimizes cost, weight, and performance.

- Enhanced Coatings: Advanced coating technologies are being used to improve the corrosion resistance and conductivity of aluminum busbars.

- Compact Designs: As the need for space-efficient solutions grows, busbars are being designed to be more compact while maintaining their performance capabilities.

- Sustainable Materials: There is a growing trend towards using recycled materials in the production of busbars, contributing to sustainability efforts in the electrical industry.

Conclusion

In summary, aluminum and copper busbars are essential components in modern electrical systems, offering efficient and reliable power distribution. Their unique properties make them suitable for a wide range of applications, from industrial settings to renewable energy systems. When choosing between aluminum and copper, it’s important to consider factors such as conductivity, cost, weight, and environmental conditions to select the best material for your specific needs.

Aluminum and copper busbars are not only highly efficient electrical conductors but also pivotal in the seamless operation of power systems. These busbars provide excellent conductivity, durability, and reliability, making them the preferred choice for various applications, including power distribution systems, electrical panels, and renewable energy setups. When selecting the ideal busbar material, factors such as current-carrying capacity, cost, weight, and environmental conditions must be considered to ensure optimal performance and longevity.

By understanding the advantages and applications of aluminum and copper busbars, engineers and electricians can make informed decisions that enhance the efficiency and reliability of their electrical installations.