The AP Precision Advantage: CNC Machining, Laser Cutting, Sheet Metal Fabrication & Prototyping Solutions

1. CNC Machining: Precision Engineered Every Time

CNC machining at AP Precision combines cutting-edge equipment, skilled technicians, and rigorous quality control. We specialize in:

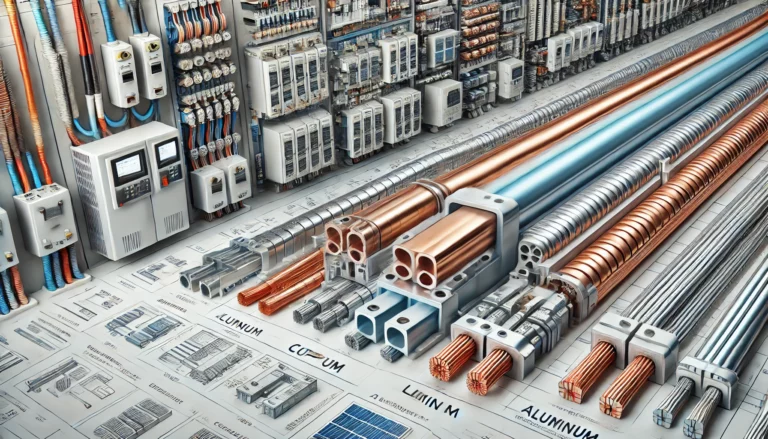

- High-precision milling and turning on components made from aluminum, stainless steel, and specialty alloys.

- Tight tolerances often within ±0.001″ for aerospace, defense, and semiconductor applications.

- Efficient runs — from one-offs to full production volumes — delivered on time and on budget.

With ISO-compliant quality checks and in-house metrology, we ensure every part aligns with your exact specifications.

2. Laser Cutting: Fast, Clean, and Consistent

Laser cutting is the perfect complement to CNC machining when it comes to intricate or high-volume metal fabrication. AP Precision offers:

- Precise cutting of sheet metal using CO₂ or fiber laser technology.

- Minimal heat-affected zones and burr-free edges, reducing secondary finishing.

- Fast file-to-part turnaround for materials like steel, aluminum, copper, and plastics.

Our advanced controls and expert technicians ensure parts are uniform and production-ready, even for large batch runs.

3. Sheet Metal Fabrication: Custom Solutions That Stand Up to the Task

From enclosure panels to structural brackets, AP Precision’s sheet metal fabrication services deliver reliability and durability. Key capabilities include:

- High-precision bending and forming using press brakes and turret punches.

- Secondary operations like welding, tapping, and assembly performed in-house.

- Proven expertise with materials like galvanized steel, stainless steel, aluminum, and specialty alloys.

We collaborate with you from design through production to ensure each part meets function and finish requirements without unnecessary cost overhead.

4. Prototyping: Bringing Your Vision to Life

AP Precision understands the critical role prototyping plays in product innovation. Our rapid prototyping capabilities include:

- Quick-turn CNC prototypes to verify fit, form, and function — even in one-off builds.

- Iterative feedback cycles, allowing design improvements before full-scale production.

- Ability to prototype parts in the same metals used for final production, providing true performance insight.

This rapid and responsive process helps reduce risk, catch design issues early, and accelerate time to market.

5. Why Choose AP Precision?

Here’s what sets us apart as a reliable manufacturing partner:

- Integrated Capabilities: All services are in-house—no back-and-forth between vendors—ensuring tighter schedules and consistent quality.

- Quality & Compliance: ISO-certified processes backed by industry-leading inspection tools guarantee your parts are right every time.

- Technical Expertise: Our engineers and technicians collaborate early in the process to recommend cost-saving design adjustments.

- Scalability: Whether you need one prototype or 10,000 units, we scale without sacrificing precision or lead times.

- Industry Focus: Proven track record in aerospace, defense, industrial automation, electronics, and more.

6. Industry-Specific Applications

Our precision services are an ideal fit across multiple industries:

- Aerospace & Defense: Components that consistently meet stringent regulatory and performance specifications.

- Electronics: Enclosures, heat sinks, and fine-detail parts for high-tech devices.

- Automation & Industrial: Custom brackets, machine parts, and control panels built for durability and precision.

- Medical & Semiconductor: Precision-critical parts used in cleanroom and regulated environments.

7. How We Work With You

- Consultation & RFQ: We review your drawings, designs, or initial concepts and discuss materials, tolerances, and volume.

- Quote & Design Review: You get a transparent quote with Design for Manufacturability (DFM) recommendations to optimize cost and performance.

- Prototype & Validate: Fast-turn prototypes help validate before committing to full production.

- Full Production: Once approved, we scale efficiently, manage quality control, and ship on schedule.

- Ongoing Partnership: We support design updates, new revisions, and reorder cycles long after the initial run.

Contact AP Precision Today

Looking to streamline your next project with a precision manufacturing partner that delivers high-quality, reliable results? Contact us to discuss your specific needs—whether it’s prototyping a new design or scaling up production for OEM quantities.