Aluminum Busbars

Table Of Contents

Aluminum Busbars | Understanding the Benefits and Applications of Aluminum Busbars

Key Takeaways

- Overview of aluminum busbars and their significance

- Various categories of aluminum busbars are available

- Different uses of aluminum busbars in industries

- Benefits of utilizing aluminum busbars over alternatives

- Steps for the setup and upkeep of aluminum busbars

- Assessment of aluminum busbars against other materials

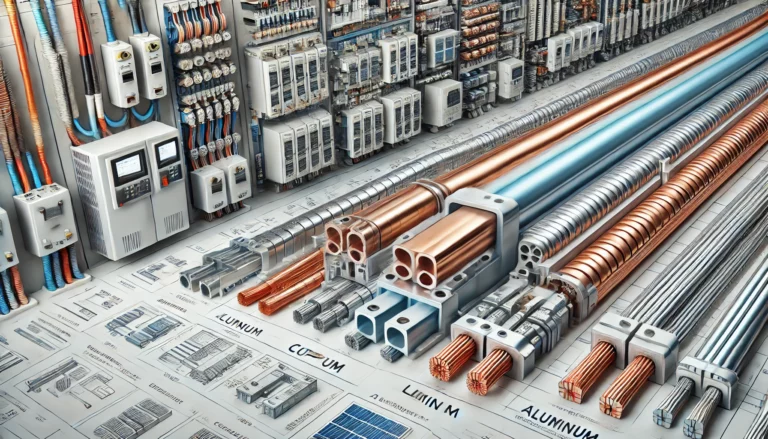

Aluminum Busbars | Understanding Aluminum Busbars

Aluminum busbars serve as essential components in electrical distribution systems, acting as conductive pathways for transporting electrical energy. These bus bars are typically made from aluminum due to their lightweight nature and cost efficiency, making them a popular choice in various applications. Unlike their copper counterparts, aluminum busbars require careful consideration of their thermal and electrical properties to ensure optimal performance. The design of busways often incorporates these busbars, facilitating easy installation and maintenance while minimizing space requirements. Understanding the characteristics and advantages of aluminum busbars is crucial for any electrical project.

Alumimum Busbars | What Are Aluminum Busbars?

Aluminum busbars are conductive bars made from aluminum, designed to distribute electrical power efficiently in various systems. These busbars serve as a critical component in electrical installations, often found in power distribution systems, substations, and switchgear. Their lightweight nature makes them easier to handle during installation and transportation compared to other heavier materials. With the growing demand for efficient and cost-effective electrical solutions, aluminum busbars have become increasingly popular in modern electrical applications.

Busways utilize aluminum busbars to minimize energy loss while providing a reliable means of power distribution. The inherent properties of aluminum allow these busbars to support higher current loads, making them ideal for industrial settings. As businesses and industries seek to enhance their infrastructure, aluminum busbars emerge as a viable solution due to their balance of performance and affordability in the transportation of electricity.

Key Properties of Aluminum Busbars

Aluminum busbars are recognized for their exceptional strength-to-weight ratio, making them a popular choice in various applications. Their lightweight nature is particularly beneficial in vehicle manufacturing, where reducing overall weight can improve fuel efficiency. The inherent properties of aluminum allow for easier handling and installation, which can significantly lower labor costs during deployment.

Corrosion resistance is another key property of aluminum busbars. This characteristic ensures longevity when installed in challenging environments, including outdoor or industrial settings. The use of aluminum enhances the durability of busbars, minimizing the need for frequent maintenance. With their excellent conductivity, aluminum busbars provide efficient power distribution, ensuring optimal performance across numerous electrical systems.

Types of Aluminum Busbars

Aluminum busbars play a crucial role in electrical systems by providing a reliable means of conducting electricity. Among the various busbar products available, flat aluminum busbars and round aluminum busbars are the most common varieties. Flat aluminum busbars are typically used for applications requiring a low profile and ease of installation, while round aluminum busbars offer flexibility in design and are ideal for compact spaces. Both types of busbars—aluminum provide excellent conductivity and are favored in many industrial and commercial settings due to their lightweight nature. Understanding the distinctions between these types enhances the selection process for effective electrical distribution solutions.

Flat Aluminum Busbars

Flat aluminum busbars are widely used in various electrical applications due to their efficient design and versatility. They provide a robust solution for power distribution, allowing for the easy transmission of electrical currents. Their flat shape makes them suitable for compact installations, particularly in tight spaces where large busbars may be unwieldy. The aluminum busbar system can be tailored to fit specific needs, accommodating different current ratings and configurations.

The advantageous properties of flat aluminum busbars include their lightweight nature and superior thermal conductivity. These aluminum busbars are easier to handle and install compared to heavier materials. The design allows for effective heat dissipation, reducing the risk of overheating during operation. This makes flat aluminum busbars a reliable choice in high-demand environments, ensuring efficient power management without compromising safety or performance.

| Busbar Model | Dimensions (mm) | Current Rating (A) | Weight (kg/m) |

|---|---|---|---|

| Model A | 50 x 5 | 400 | 1.5 |

| Model B | 100 x 10 | 800 | 3.0 |

| Model C | 75 x 8 | 600 | 2.0 |

| Model D | 120 x 12 | 1000 | 4.0 |

Round Aluminum Busbars

Round aluminum busbars are a crucial component in electrical distribution systems, designed to facilitate the efficient transfer of electrical energy. Their circular shape allows for enhanced current flow and minimizes electrical resistance, making them a popular choice for specific applications. The busbar construction involves a robust aluminum alloy that not only ensures durability but also supports the weight of electrical loads. In a busbar system, these round configurations can easily be integrated with a series of aluminum busbars, providing a flexible solution for various power requirements.

The versatility of round aluminum busbars makes them suitable for numerous applications. Their design enables them to accommodate a considerable amount of current while maintaining thermal efficiency, making them ideal for high-capacity environments. As engineers consider their next busbar application, round busbars offer numerous benefits, including easy installation and maintenance. These attributes make aluminum busbars a favored option among industry professionals seeking reliable solutions for electrical conduction.

Applications of Aluminum Busbars

Aluminum busbars are essential components in various applications, particularly in electrical power distribution and industrial equipment setups. Their lightweight construction makes these busbar offerings ideal for situations where space and weight constraints are critical. The aluminum bus bar provides effective distribution of electrical currents, while thin busbar configurations allow for versatile installation options. Lightweight busbar solutions in aluminum enhance efficiency and reduce installation complexity, making them a preferred choice in modern electrical systems. As industries continue to evolve, the demand for reliable and efficient aluminum busbars remains high, driving innovation in design and application.

- Ideal for power distribution in electrical substations

- Suitable for use in renewable energy systems, such as solar and wind power

- Commonly used in data centers for efficient electricity distribution

- Employed in transportation systems, including rail and electric vehicle charging stations

- Utilized in industrial machinery and equipment to manage electrical connections

- Integral to telecommunications infrastructure for reliable signal transmission

- Effective for electrical panel boards and switchgear applications

Electrical Power Distribution

Aluminum busbars play a crucial role in electrical power distribution systems. They serve as efficient conductors of electricity, providing a reliable means of transferring current between various components. Compared to copper busbars, aluminum busbars offer significant weight savings and cost efficiency while maintaining optimal performance. The use of horizontal-profiled busbars is particularly prevalent in large-scale applications, where space and weight considerations are paramount. Innovations in busbar manufacturing continue to enhance their effectiveness in handling high current loads without compromising on safety.

The integration of aluminum busbars into electrical power distribution networks not only streamlines connectivity but also reduces installation complexities. Their lightweight nature allows for easier handling and installation in various setups, making them a preferred choice for many engineers. As industries seek cost-effective solutions without sacrificing performance, aluminum busbars emerge as a versatile option, adapting to diverse operational demands. Properly designed and maintained busbar systems ensure minimal energy loss and improved reliability in power distribution.

Industrial Equipment

Aluminum busbars play a crucial role in various industrial equipment applications, providing efficient power distribution and management. Their lightweight nature facilitates easier installation, while the cost-effectiveness of aluminum busbars often leads to significant savings in busbar production and installation costs. Industries utilize aluminum busbars for their reliability and performance in high-load environments, ensuring the safe and effective operation of machinery and systems.

The integration of aluminum busway systems complements the function of aluminum busbars, creating a streamlined approach to electrical distribution in industrial settings. These setups are designed to minimize resistance, enhancing overall energy efficiency. With the growing demand for robust solutions, aluminum busbars remain a preferred choice among manufacturers focusing on delivering innovative and reliable bus bar solutions.

Advantages of Using Aluminum Busbars

Aluminum busbars are recognized for their lightweight nature and cost-effectiveness, making them an attractive option in various electrical applications. The use of conductive aluminum busbars ensures efficient power distribution, which is particularly vital in high-performance environments. Compared to other bus bar materials, aluminum offers a favorable balance of performance and price, allowing for reduced installation costs while maintaining reliability. These electrical busbar products not only provide substantial current-carrying capacity but also facilitate easier handling and installation compared to heavier alternatives. Overall, the advantages of aluminum busbars make them a popular choice in modern electrical systems.

Lightweight and CostEffective

Aluminum busbars are recognized for their lightweight nature, making them ideal choices in various applications. The use of conductive aluminum busbar systems significantly reduces the overall weight of electrical installations compared to thicker busbars made from heavier materials. This characteristic not only facilitates easier handling and installation but also contributes to overall energy efficiency in electrical systems.

Another compelling advantage of aluminum busbars is cost-effectiveness. The manufacturing process and raw materials used for profile busbars result in lower production costs compared to copper alternatives. These savings are passed on to consumers while maintaining high levels of conductivity, ensuring that aluminum busbars’ performance does not fall short. The balance of performance and economic viability makes them a preferred choice in many industries.

Excellent Conductivity

Aluminum busbars are renowned for their excellent conductivity, making them a preferred choice for various electrical applications. The efficient current-carrying capacity of aluminum busbars rivals that of copper bus bars, with innovations in design ensuring optimal performance. Using rectangular bar bus configurations allows for efficient space utilization, making these busbars ideal for both large and compact installations. Their performance is vital in systems demanding high reliability, such as in battery busbars that power electric vehicles and renewable energy systems.

Choosing the correct bus bar material can significantly impact overall system efficiency. With trending applications in electrical distribution, aluminum busbars provide a lighter alternative without sacrificing conductivity. While copper bus bars have traditionally been favored, advances in aluminum technology have elevated the use of aluminum busbars, proving them to be a competitive option. The synergy of lightweight construction and high conductivity makes aluminum busbars an essential component in modern electrical infrastructure.

Installation and Maintenance of Aluminum Busbars

Proper installation and maintenance of aluminum busbars are crucial for ensuring their optimal performance in electrical systems. Utilizing high-quality bus bar fasteners is essential to secure connections, minimizing the risk of electrical resistance and potential overheating. Various products, such as electrical aluminum bus connectors, enhance the reliability of connections in multiple bar bus configurations. Regular inspections should include checking for corrosion or damage, particularly in potential equalization busbars, to maintain electrical integrity. Following manufacturer guidelines during installation and adhering to best practices for maintenance can significantly extend the lifespan of aluminum busbars, ensuring efficient operation in diverse applications.

Installation Guidelines

Proper installation of aluminum busbars is crucial for ensuring efficiency and reliability in electrical bus systems. It is essential to select the appropriate bus bar connectors tailored to the specific requirements of the setup. The correct sizing and spacing of electrical aluminum bus should be determined by the expected current load, ambient temperature, and the overall design of the system. Ensuring that the busbars are securely mounted will help minimize the risk of mechanical failure.

Safety precautions must be observed throughout the installation process. Proper grounding of the electrical bus bars is vital to avoid any potential electrical hazards. Using insulated tools while handling aluminum busbars can reduce the risk of accidents. Regular inspection and monitoring of the connections and bus systems will ensure long-term performance and safety, contributing to the effective operation of the electrical infrastructure.

Maintenance Best Practices

Regular inspection of aluminum busbars is essential to ensure optimal performance and longevity. Any signs of corrosion, discoloration, or physical damage should be addressed promptly. Information from busbar manufacturing guidelines can provide insights into the necessary maintenance schedule. Proper cleaning techniques should be employed to remove contaminants, as these can affect conductivity and overall operation efficiency.

Routine checks on connections and terminations are crucial for preventing failures in an aluminum busbar system. Ensuring that all connections are tight and secure minimizes resistance and heat build-up. Using high-quality materials, such as CCA bus, where applicable, can enhance durability. Always refer to specific maintenance manuals to tailor practices to the particular type of aluminum bar being utilized.

| Maintenance Task | Frequency | Recommended Cleaning Method | Potential Issues if Not Addressed |

|---|---|---|---|

| Visual Inspection | Monthly | Dry cloth or brush | Corrosion, discoloration, damage |

| Connection Checks | Quarterly | Torque wrench application | Increased resistance, heat build-up |

| Surface Cleaning | Annually | Non-abrasive cleaner | Affected conductivity, lower efficiency |

| Replacement of Damaged Sections | As needed | N/A | System failures, outages |

Comparison with Other Materials

Aluminum busbars are often compared to other conductive materials, such as copper, primarily due to their differing properties and performance under equivalent loads. While aluminum busbars are lighter and more cost-effective, copper offers superior conductivity, which can be crucial in applications requiring high efficiency. However, aluminum busbars can still perform admirably when designed correctly, with thorough pretreatment enhancing their durability and resistance to corrosion. Both materials have their advantages and drawbacks, making the selection process dependent on specific application requirements and operational parameters. Ultimately, the choice between aluminum and copper busbars hinges on the balance between cost, weight, and required performance in the designed conductive bus system.

- Aluminum is lighter than copper, making it easier to handle and install.

- Copper has a higher conductivity than aluminum, resulting in better energy efficiency in certain applications.

- Aluminum is generally more cost-effective compared to copper, allowing for budget-friendly solutions.

- Aluminum busbars require pretreatment for enhanced durability and corrosion resistance.

- The selection between aluminum and copper often depends on specific application requirements, such as load and environmental factors.

- Copper may be preferable in high-efficiency applications despite its higher cost.

- Both materials can be optimized for performance when properly designed and tested.

Aluminum vs. Copper Busbars

Aluminum busbars are often favored in various applications due to their lightweight nature and cost-effectiveness. The width and design of these bars provide flexibility for installation in tight spaces, making them an easy choice for many electrical systems. Their relatively low weight not only simplifies the installation process but also reduces the overall structural load on the supporting infrastructure.

Copper busbars offer excellent conductivity but tend to be heavier and more expensive. Although they may perform better in certain high-current applications, aluminum busbars can still provide satisfactory performance while being easier to handle. This makes aluminum a competitive option for those seeking reliable electrical solutions without the added burden of heavy materials.

Performance Considerations

Aluminum busbars exhibit specific performance characteristics that distinguish them from other materials used in electrical conduction. Their lightweight nature makes them ideal for situations where structural support is limited. When evaluating the area and dimensions of flat bar configurations, aluminum busbars provide a favorable strength-to-weight ratio. This unique property ensures that they can handle significant electrical loads while maintaining structural integrity.

The thermal and electrical conductivity of aluminum busbars also plays a crucial role in their overall performance. While table comparisons may favor copper in terms of conductivity, aluminum’s properties make it suitable for various applications, especially in large-scale electrical distribution settings. The specific design of aluminum busbars can optimize their efficiency, influencing the choice of materials based on required performance criteria and installation environments.

Conclusion

Aluminum busbars play a crucial role in modern electrical systems, offering advantages such as lightweight design and cost-effectiveness. The characteristics of flat aluminum busbars make them suitable for various applications, including electrical power distribution and industrial equipment. Their performance, when compared to other materials like copper, highlights the significance of selecting the right material based on area requirements and efficiency. A comprehensive table comparing different busbar materials helps in understanding the benefits and limitations of aluminum busbars. Overall, their excellent conductivity and practical applications solidify their position as a preferred choice in the industry.

FAQS

What are the benefits of using aluminum busbars over traditional alternatives in electrical systems?

Aluminum busbars are increasingly popular due to their lightweight characteristics and efficiency in electrical busway systems. They can effectively handle equivalent loads while providing busbars. quick solutions for various applications. If you need lightweight busbar-solutions aluminum, you’ll find that our products include options for series aluminum busbars and other electrical aluminum bus offerings. Feel free to request an aluminum busbars. quick quote for your project needs or to gain more information on busbar manufacturing.

What information can you share about alumimum busbars and how they compare to aluminium busway in electrical applications?

Aluminum busbars are essential components in electrical systems, providing excellent conductivity and efficiency. Compared to aluminium busway, which is another popular choice, alumimum busbars can be more versatile in various applications. For detailed information on products like electrical aluminum bus and insights on busbar manufacturing, various resources are available to help you make the best choice for your electrical needs.

What information can you provide about the manufacturing process of aluminum bus products in electrical applications?

The manufacturing process of electrical aluminum bus products involves several steps, including material selection, cutting, shaping, and finishing. This ensures that the busbars are made to meet specific electrical requirements and standards. For more detailed information, you can consult resources focused on busbar manufacturing techniques and their applications in various electrical systems.

What information can you provide about aluminum bus products in electrical applications and their manufacturing process?

Aluminum bus products in electrical applications are essential components that conduct electricity efficiently. The manufacturing of these busbars involves several processes, including the shaping and finishing of aluminum to ensure optimal performance in electrical connections. High-quality aluminum bus products are designed to withstand various environmental conditions and facilitate effective current distribution, making them indispensable in modern electrical systems.

What are some key details about the manufacturing of electrical aluminum bus products and what information should designers consider?

When designing electrical systems, it’s crucial to understand that aluminum bus products play a vital role in ensuring efficient power distribution. The manufacturing process of these products involves precise techniques that enhance their durability, conductivity, and overall performance. Key information designers should consider includes the specifications related to busbar manufacturing, material properties of aluminum, and how these factors influence the efficiency of the electrical systems in which the aluminum bus products are utilized.

What important information should be considered regarding the manufacturing of electrical aluminum bus products?

When discussing electrical aluminum bus products, it’s essential to gather comprehensive information on busbar manufacturing processes, as this impacts performance and reliability in electrical systems. Understanding the nuances of the aluminum bus manufacturing methods can greatly assist designers in selecting the right products for their applications.

What important details should designers focus on when considering the products used in electrical aluminum bus systems and the information related to busbar manufacturing?

Designers should focus on several key details regarding electrical aluminum bus products. This includes understanding the importance of selecting the right materials for conductivity and thermal performance, as well as being aware of the information surrounding busbar manufacturing techniques. Proper knowledge in these areas ensures optimal performance and reliability of electrical aluminum bus systems.

What information do designers need to keep in mind about electrical aluminum bus products and their manufacturing processes?

Designers should focus on understanding the key details of electrical aluminum bus products, including the different types available, their applications, and the specific information regarding busbar manufacturing that can impact performance and efficiency. Understanding these aspects will lead to better decision-making in the design and application of electrical aluminum bus systems.

What key details should researchers keep in mind about the efficiency of electrical aluminum bus products in different applications?

Researchers should consider the efficiency, reliability, and cost-effectiveness of electrical aluminum bus products when evaluating their performance in various applications. Additionally, it’s important to gather information on busbar manufacturing techniques to ensure optimal design and functionality.

What important factors should be assessed in the design of electrical aluminum bus products, particularly regarding busbar manufacturing?

When designing electrical aluminum bus products, it’s essential to consider factors such as material properties, load requirements, and thermal management. Additionally, understanding the busbar manufacturing process can provide valuable information that impacts performance, safety, and efficiency in various electrical applications.