Essential Winter Welding Checks and Inspections for Optimal Safety and Performance

Key Takeaways

- Significance of Assessing Welds in Cold Weather

- Essential Focus Points for Welding Evaluations Before Winter

- Optimal Approaches for Home Welding in Winter

- Expectations from Expert Welding Evaluations

- Modifying Welding Methods for Cold Weather

- Frequent Problems Identified in Winter Welding Assessments

Importance of Welding Inspections During Winter

Winter welding checks are crucial for ensuring the integrity and safety of welded structures during colder months. The harsh winter environment can impact the performance of welding machines and the quality of welds, making regular welding inspections essential. Professional welding inspectors evaluate factors such as equipment functionality and the effects of welding fumes on both the welder and the environment. Ensuring that welded metalwork adheres to safety standards is vital for preventing failures that could arise from inadequate checks. Proper attention to winter welding checks helps guarantee that both the welders and the structures they create remain safe and reliable throughout the season.

| Inspection Factor | Description | Importance |

|---|---|---|

| Equipment Functionality | Assessment of welding machines and tools to ensure they are operational. | Prevents equipment failure and ensures quality welds. |

| Welding Technique | Evaluation of the welding techniques used by personnel in winter conditions. | Enhances weld strength and reduces the risk of defects. |

| Fume Management | Monitoring the control and extraction of welding fumes. | Protects the health of welders and maintains a safe work environment. |

| Material Integrity | Checking the properties of metals being welded, including temperature impacts. | Ensures reliable and durable welding outcomes in cold weather. |

Overview of Winter Welding Inspections

Winter welding checks are crucial for ensuring the integrity of welds made in cold conditions. Inspections should focus on potential issues like cold cracking and metal fatigue, which can compromise the strength of steels. It is essential for welders to conduct thorough inspections using tools like flashlights to identify any defects or areas needing repairs. Proper protective gear, including steel toes, is vital for safety during these checks.

Attention to detail during winter welding inspections can prevent serious failures in metal structures. The cold can affect the behavior of steel, making it more susceptible to issues that could arise without proper oversight. Regular inspections help identify vulnerabilities that might not be visible at first glance. Ensuring that every weld meets quality standards is imperative for maintaining durability and safety in winter conditions.

Risks Associated with Inadequate Winter Welding Checks

Inadequate winter welding checks can lead to severe implications for the integrity of structural steel and other metals. Insufficient assessments can result in cracking or other defects that compromise the safety of welded joints. Proper evaluations involving material handling equipment and protective coatings are essential to ensure that the welds can withstand harsh winter conditions. Failure to conduct thorough inspections, such as magnetic particle inspection, increases the risk of structural failures that can have dire consequences for the overall project.

The working conditions during winter may exacerbate issues related to fuel filters and process heat, further complicating the welding process. Without diligent winter welding checks, fabrications may fail to meet necessary standards, leading to costly repairs and safety hazards. The unique challenges posed by low temperatures require vigilant oversight to avoid critical failures. Unattended welding issues during cold months can easily escalate, putting both workers and infrastructure at significant risk.

Key Areas for Pre-Winter Welding Inspections

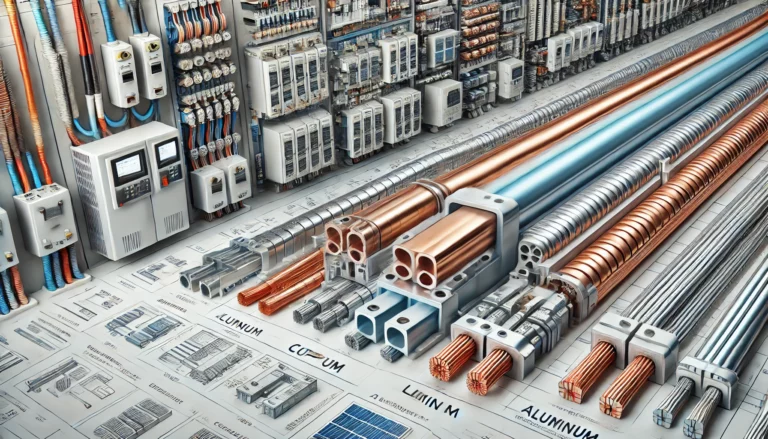

Effective pre-winter welding inspections focus on crucial elements to ensure safety and quality during the colder months. One significant area is the evaluation of materials, particularly aluminum and coatings, as they may respond differently under winter weather conditions. Conducting thorough winter welding checks includes assessing the operating temperature and ensuring proper heating methods, such as electric heating, are in place for both the workspace and the welding equipment. Heavy equipment must be inspected to confirm that all machines can perform effectively in low temperatures, while also guaranteeing that any snow buildup is managed to prevent hazards. Prioritizing these areas will enhance the overall safety and efficiency of winter welding operations.

Material Evaluation for Winter Conditions

Winter welding checks focus on evaluating materials to ensure their suitability for low temperatures. At frigid temperatures, certain materials can become brittle, compromising structural integrity. Regular winter welding inspections are critical for identifying potential failures in materials designed for warmer climates. Gas mixtures may also react differently in cold conditions, necessitating thorough preventive maintenance to ensure optimal performance.

Comprehensive winter welding projects require a meticulous assessment of materials before initiation. The selection of appropriate alloys can significantly influence the quality of the weld and the longevity of the structure. Regular winter welding checks help prevent issues related to material fatigue and ensure that the components can withstand extreme cold. Proper maintenance routines tailored for winter conditions are essential to uphold the safety and durability of completed welds.

Equipment and Tool Functionality Checks

Ensuring proper functionality of welding equipment is crucial during winter welding checks. Cold temperatures can affect the performance of tools and gear, potentially leading to improper welding techniques. A comprehensive welding inspection should include a thorough evaluation of all equipment used in the welding setup. It’s essential to verify that the welding jackets are in good condition, as they protect against both the cold and sparks during the welding process. Any defects in the tools can hamper the quality of the welding job and may require adjustments to the specific welding applications being completed.

Regular checks of equipment prior to starting a project can prevent issues that stem from previous welding work. Identifying problems early on can also facilitate the selection of appropriate welding techniques suited to the climatic conditions. A cold environment can impact the melting rates and penetration of welds, making it vital to ensure that the welding equipment is well-calibrated. Failure to perform these checks can lead to significant delays and costly rework in the welding process. Prioritizing functional checks will ultimately enhance the outcome of the winter welding checks and ensure safety and quality in every welding job.

- Regularly inspect welding machines for signs of wear or malfunction.

- Ensure welding cables and connections are in good condition and free from damage.

- Check gas levels and flow rates for torch equipment to ensure consistent performance.

- Test safety equipment, including gloves and helmets, for any signs of damage or wear.

- Verify that the appropriate welding rods or filler materials are available and suitable for winter conditions.

- Calibrate welding equipment to account for cold temperatures that may affect performance.

- Maintain a clean work area to prevent accidents and ensure safe operation during cold weather.

Best Practices for Residential Winter Welding

Conducting comprehensive winter welding checks is crucial for ensuring quality welding during colder months. Utilizing insulated welding gloves can protect professionals from cold while welding, enhancing both comfort and precision. Mobile welding offers flexibility for residential projects, allowing certified welders to perform essential welding work in various locations. Maintaining equipment is vital; regular welder repair ensures that tools function optimally in harsh conditions. Using welding tents can provide necessary protection from the elements, facilitating a safer work environment. Engaging professional welder services for winter welding checks can prevent potential issues associated with aluminum welding and ensure that safety protocols are consistently met. Mobile welding inspectors play a vital role in assessing the quality of welding work, ensuring that all standards are upheld.

Preparing the Workspace for Cold Weather

A thorough workspace preparation is essential for successful winter welding checks. Hobby welders must focus on conducting pre-winter inspections to ensure all welded components are ready for cold conditions. Properly heated work areas can significantly enhance the quality of welded joints, preventing issues that arise from cold metal. AWS-certified welders often emphasize the importance of maintaining a controlled environment to facilitate effective welding of structures like welded railings and other projects.

Implementing equipment winterization tips can help safeguard tools against freezing temperatures. Ensuring that welding machines and accessories are in top shape is crucial for optimal performance. A winter check-up of the equipment can prevent malfunction and create a smoother welding experience. Ensuring all necessary supplies are readily accessible enables a hobby welder to remain productive despite the colder weather.

Choosing the Right Welding Technique for Winter Projects

Selecting the appropriate welding technique for winter projects is crucial to ensuring high-quality welds, especially under cold conditions. Winter welding checks must be carried out to assess the impact of low temperatures on weld quality. Techniques that promote uniform welds and maintain internal weld integrity should be prioritized. Ensuring the right approach can help to minimize the risks of compromised welds and potential weld failures, which can lead to costly repairs and safety issues down the line.

Cold-weather equipment prep plays a significant role in executing effective welding techniques during winter. Inspecting tools and machines before commencing work can prevent failures and enhance the functionality of welded seams. Incorporating inspection tips into regular assessments helps ensure that all aspects of the welding process, from equipment to technique, are optimized for the cold. Implementing a thorough inspection today can pave the way for successful winter welding projects that stand the test of time.

- Ensure all welding equipment is well-maintained and free from ice buildup.

- Choose welding rods designed for low-temperature conditions.

- Preheat the metals to be welded to reduce the chances of cracking.

- Use proper clothing and gear to protect against cold exposure during welding.

- Monitor environmental conditions, including wind and humidity, as they can affect weld quality.

- Consider the use of windbreaks to shield the work area from harsh winter winds.

- Plan projects during the warmest part of the day whenever possible.

Professional Welding Inspections: What to Expect

Scheduling a professional inspection for winter welding checks is essential to ensure the integrity and reliability of welds during cold weather. A thorough inspection focuses on critical aspects, including the weld area and the potential for incomplete welds that may arise due to the rapid cooling of metal. Inspectors evaluate inspection results and generate detailed inspection reports, which highlight any concerns and recommend necessary repairs or fabrication adjustments. These evaluations help guarantee that industrial winter projects maintain the highest quality and safety standards, allowing for the creation of reliable welds even in challenging conditions. Properly conducted winter welding checks serve to protect both the structure and the welder’s investment.

Scheduling and Planning for Winter Welding Projects

Proper scheduling of winter welding checks is crucial for successful project execution. Winter challenges can complicate the welding process, especially with issues like equipment rust and the expansion of surrounding metal. Planning for routine inspections helps identify necessary repairs before work begins. A heated shop can mitigate some temperature-related issues, allowing for more effective welding and ensuring the weld zone remains within acceptable temperature parameters.

Effective planning also involves ensuring that all protective equipment is in place and functional. During winter welding checks, it’s essential to assess the equipment’s overall condition and readiness for the task. By investing time in planning, welders can anticipate and address potential obstacles associated with colder weather, leading to safer and higher-quality welds. Understanding these factors plays a vital role in the success of winter welding projects.

| Welding Equipment | Inspection Schedule | Maintenance Actions |

|---|---|---|

| Welding Machine | Weekly | Check for rust, and clean input/output connections |

| Protective Gear | Before Each Use | Inspect for damage, and ensure proper fit |

| Gas Cylinders | Monthly | Check for leaks, and ensure proper storage |

| Welding Tools | Every Two Weeks | Sharpen, clean, and replace as necessary |

| Safety Equipment | Weekly | Test functionality of alarms and fire extinguishers |

Cost Considerations for Professional Inspections

Professional inspections for winter welding checks are an investment in quality and safety. A thorough inspection can uncover potential issues with fabrication techniques before they escalate into costly repairs. This applies particularly to projects involving metal awnings, where the integrity of the welds is critical. Regular inspections not only ensure compliance with safety standards but also provide peace of mind during cold weather applications.

Cost considerations also extend to the materials and methods used in winter approaches. Utilizing winter-blend fuel for equipment and ensuring that all tools are suited for cold weather can influence overall project costs. Preventive repairs identified during the residential inspection process help maintain quality and prolong the lifespan of welded structures. Prioritizing winter welding checks can ultimately save time and money by minimizing the risk of extensive damage later on.

Adapting Welding Techniques for Winter Conditions

Effective winter welding checks involve several key adjustments to ensure quality and safety in cold conditions. Special attention must be paid to the potential for ice-related damage and the impact of snow loads on structures like custom metal fencing. Cold drafts present challenges that can affect weld consistency and lead to failed welds if not properly managed. Regular maintenance checks of process equipment and frozen valves are critical to prevent complications during winter projects. Employing proper winter welding techniques ensures the integrity of the welds in harsh environments, thereby safeguarding against the risks associated with inadequate inspections.

Selecting Appropriate Equipment for Cold Weather

Proper winterization of equipment is essential for successful winter welding checks. Harsh winter elements can significantly impact the functionality of welding tools and machinery. Experienced inspectors recommend conducting thorough visual inspections to identify any potential issues. This includes checking metal surfaces for corrosion, inspecting belts for wear, and ensuring all components are adequately lubricated. Regular equipment maintenance is crucial to prevent mid-winter breakdowns that could stall projects.

Selecting the right equipment for cold weather involves understanding temperature considerations that affect welding performance. Utilizing tools designed for lower temperatures can enhance the efficiency and safety of the welding process. Consulting with an industrial gas supplier can provide insights on materials and gases suited for winter conditions. Conducting winter welding checks on equipment ensures that welders can work effectively and safely throughout the season.

Ensuring Quality and Safety in Winter Welding

Winter welding checks are crucial for ensuring that welds can withstand the rigors of cold weather. Inspectors should pay close attention to high-strength steels and high-carbon metals, as these materials become more susceptible to cracking in low temperatures. Insulation brittle properties may also compromise the integrity of sound welds in structural steel frameworks. Addressing these concerns proactively can prevent expensive emergency repairs later.

Choosing the right materials and techniques is vital for winter welding projects. Using winter-weight engine oil for machinery can enhance performance in colder conditions. Welders must also be vigilant about the potential for distortion or stress in weld joints due to extreme temperature fluctuations. Timely and thorough winter welding checks are essential to uphold safety standards and ensure reliable structural integrity under winter weather conditions.

Common Issues Found in Winter Welding Inspections

Winter welding checks often reveal a range of common issues that can arise due to colder conditions. The thermal effects of cold weather can significantly impact the performance of welding equipment, leading to risks of damage if not addressed. Techniques that work well in warmer months may falter in the cold, resulting in improper fusion or weak joints. As the cooling process occurs quickly in winter, it becomes essential to conduct thorough testing of the equipment and materials used. Identifying these problems early in the winter welding checks not only ensures quality workmanship but also promotes safety throughout the entire welding process.

Conclusion

Winter welding checks are essential for ensuring safety and quality during cold-weather projects. Proper maintenance of equipment and materials is crucial, as extreme temperatures can affect the structural integrity of welds. Regular inspections help identify potential issues before they escalate, providing peace of mind for both welders and clients. By prioritizing these checks, welders can maintain efficiency and uphold high standards, ultimately leading to successful outcomes in winter welding endeavors.

FAQS

What are the key considerations for comprehensive welding inspections during winter to ensure the quality of welded parts?

During winter, it’s crucial to conduct comprehensive welding inspections because the welding work can be affected by the cold temperatures. As the metal cools more quickly in winter, it’s essential to ensure that the welded part maintains its integrity. Professional winter welding requires specific techniques to adjust for how welds expand and contract with temperature fluctuations. Additionally, it’s important to inspect belts and other equipment used during the process to avoid any issues that could affect the quality of the welding work.

How can the impact of temperature on welding work influence the quality of welds in winter conditions?

During winter, welding work can be affected by cold temperatures, which can cause the metal to become brittle and the welds to expand differently than in warmer conditions. Ensuring proper preheating and post-weld heat treatment can help mitigate these issues, ensuring that the final welds maintain their integrity and quality.

How does the cold weather affect the durability of welds created during winter welding work?

Cold weather can significantly impact welding work, as the lower temperatures can affect the cooling rates of welds and potentially lead to cracking. Additionally, the material itself may become brittle, leading to weaknesses in the welds that expand during subsequent temperature changes.

What precautions should be taken to ensure that welding work isn done effectively in winter conditions?

To ensure that welding work isn done effectively in winter conditions, it is important to consider factors such as pre-heating the materials, using suitable filler metals, and minimizing the exposure of welds to cold temperatures right after they are completed. This helps in preventing issues as the welds expands and contracts due to the temperature fluctuations.

What strategies can be implemented to guarantee that welding work isn done correctly in extreme winter weather?

To ensure that welding work isn done effectively in extreme winter weather, it’s crucial to implement strategies such as preheating materials to combat low temperatures, using appropriate filler materials that accommodate cold conditions, and maintaining a stable work environment to reduce the impact of harsh weather on the welding process. Additionally, regular equipment checks and proper insulation of the work area can significantly enhance the quality and safety of winter welding operations.

What are the best practices to ensure that welding work wasn impacted negatively by severe winter weather conditions?

To ensure that welding work wasn adversely affected by severe winter weather conditions, it’s crucial to implement best practices such as preheating materials, using appropriate welding techniques, and utilizing specialized equipment designed for cold weather. Additionally, monitoring environmental factors and maintaining proper safety protocols can help safeguard the quality and effectiveness of the welding work.