Effective Industrial Maintenance Scheduling and Optimization Techniques

Key Takeaways

- Grasping the concept of industrial upkeep planning

- Varieties of upkeep timelines

- Advantages of planning maintenance

- Essential elements for crafting upkeep timelines

- Software solutions for maintenance planning

- Approaches for establishing a successful upkeep timetable

- Obstacles in maintenance planning

Understanding Industrial Maintenance Scheduling

Industrial maintenance scheduling is a crucial aspect of operational efficiency in manufacturing and industrial environments. It involves the strategic planning of scheduled maintenance, ensuring that routine maintenance tasks are performed to enhance equipment reliability. By implementing techniques such as total productive maintenance and predictive maintenance, organizations can effectively reduce maintenance costs while maximizing equipment uptime. A computerized maintenance management system plays a vital role in tracking maintenance activities and facilitating condition-based maintenance, allowing for timely interventions based on equipment performance. This balanced approach to maintenance not only improves productivity but also prolongs the lifespan of machinery, creating a more sustainable operational framework.

What is Industrial Maintenance Scheduling?

Industrial maintenance scheduling refers to the systematic planning of maintenance activities within industrial settings, including sectors like aircraft maintenance and facility management. This process involves both preventive maintenance and corrective maintenance, ensuring that equipment operates smoothly and efficiently. Schedulers carefully analyze the requirements of various machines and systems, leveraging tools for capacity planning to optimize maintenance windows and resource allocation.

Effective industrial maintenance scheduling acts as a roadmap for maintenance teams. Schedulers prioritize tasks based on equipment criticality and condition, tracking both scheduled and unscheduled maintenance activities. This approach minimizes equipment failures and maximizes operational uptime, making it essential for maintaining high productivity levels in any industrial environment.

Importance of Effective Maintenance Scheduling

Effective industrial maintenance scheduling plays a crucial role in ensuring operational efficiency across various sectors. By implementing a robust preventative maintenance strategy, facilities management teams can proactively address machinery needs before they escalate into significant issues. This foresight minimizes costly downtime and enhances the performance of machines, allowing for smoother operations and better project management. Utilizing project management software can streamline this process, enabling teams to allocate resources efficiently and maintain a clear overview of maintenance tasks.

The impact of well-structured maintenance schedules extends beyond immediate repairs. Strategic industrial maintenance scheduling fosters a culture of reliability, where machines operate at peak performance for longer periods. This reliability not only reduces operational disruptions but also supports the overall goals of project management by adhering to timelines and budget constraints. Facilities management teams that prioritize effective maintenance scheduling position their organizations for long-term success and improved machinery lifespan, thus reinforcing the importance of this practice in today’s industrial landscape.

Types of Maintenance Schedules

Different approaches to industrial maintenance scheduling ensure that operations run smoothly and efficiently. Time-based maintenance schedules focus on regular inspections and repairs based on predetermined intervals, helping businesses maintain optimal equipment performance. Condition-based maintenance schedules rely on real-time data to determine the necessity of maintenance, enhancing capacity utilization and minimizing unnecessary downtime. Corrective maintenance schedules address equipment failures as they occur, improving logistics and potentially impacting overall productivity. By integrating these approaches with business rule management systems and automation, manufacturers can streamline inventory management and reduce the likelihood of unexpected equipment failures.

Time-Based Maintenance Schedule

A time-based maintenance schedule is a proactive approach in industrial maintenance scheduling where maintenance tasks are performed at regular, predetermined intervals. This method ensures that machinery and equipment receive timely attention based on time rather than their condition. Implementing management software can streamline the planning process, integrate standard operating procedures, and reduce the need for workarounds. This structured approach promotes energy management, enhances productivity, and ultimately supports improved workforce productivity within a manufacturing environment.

Establishing a time-based maintenance schedule helps organizations maintain consistent operational efficiency. Regular maintenance minimizes the risk of unexpected breakdowns that can disrupt production cycles. By aligning maintenance activities with workforce management practices, companies can better allocate resources and reduce downtime. This strategy not only boosts the reliability of equipment but also contributes positively to overall operational effectiveness in industrial settings.

Condition-Based Maintenance Schedule

Condition-based maintenance focuses on evaluating the actual condition of heavy equipment to determine when maintenance should be performed. This approach is integral to industrial maintenance scheduling as it allows technicians to conduct inspections based on real-time data rather than fixed intervals. By analyzing factors such as wear and performance metrics, companies can address optimization problems commonly faced in supply chain management. Equipment like CNC machines can benefit significantly from this method, ensuring that maintenance occurs only when necessary, thereby minimizing unnecessary interruptions.

Implementing a condition-based maintenance schedule requires strategic planning and resource allocation. Management must invest in reliable monitoring systems to gather data that informs maintenance decisions. This empowers technicians to prioritize tasks based on the equipment’s current state, leading to efficient use of resources and reduced downtime. Through diligent inspection and responsive actions, organizations can enhance their operational efficiency and extend the lifespan of critical machinery.

- Establish regular data collection intervals for monitoring equipment condition

- Utilize advanced sensors and IoT technology for real-time data analysis

- Train maintenance staff on interpreting data and making informed decisions

- Create a feedback loop to continually improve maintenance strategies

- Develop clear protocols for addressing identified maintenance needs

- Allocate budget for technology upgrades that support condition monitoring

- Monitor performance outcomes to evaluate the effectiveness of the maintenance schedule

Corrective Maintenance Schedule

Corrective maintenance is an essential component of industrial maintenance scheduling that addresses unforeseen equipment failures. This type of maintenance focuses on diagnosing and rectifying issues as they arise, often with the aid of technical support. Organizations depend on a robust supply-chain to procure necessary parts and resources required for effective repairs. By incorporating corrective strategies into comprehensive maintenance scheduling, businesses can ensure that unexpected breakdowns do not severely impact productivity.

Proper maintenance scheduling not only helps in managing corrective actions but also emphasizes the importance of regular maintenance scheduling to prevent future issues. Scheduling maintenance tasks effectively allows operators to balance corrective measures with proactive maintenance efforts. This dual approach ensures a more resilient operation, ultimately leading to heightened operational efficiency within industrial maintenance scheduling frameworks.

Benefits of Maintenance Scheduling

Effective maintenance schedules play a crucial role in enhancing the overall performance of machinery and equipment through industrial maintenance scheduling. By implementing a machine maintenance schedule that integrates preventive maintenance scheduling, organizations can significantly extend the lifespan of equipment. Industrial maintenance optimization is achieved by reducing unplanned downtime, allowing for more efficient operations and increased productivity. Scheduled maintenance work not only minimizes the likelihood of unexpected failures but also provides a solid foundation for generating thorough industrial maintenance reports. An optimal maintenance schedule can streamline processes and ensure that maintenance tasks are prioritized correctly, ultimately leading to a more reliable production environment.

Enhancing Equipment Lifespan

A well-implemented industrial maintenance scheduling strategy significantly boosts equipment lifespan. By adhering to a structured maintenance schedule, facilities can ensure that machinery receives timely care and necessary inspections. A scheduled maintenance program that incorporates routine checks and preventive measures helps to identify potential issues before they escalate. Maintenance schedulers play a crucial role in developing an effective maintenance schedule that aligns with operational demands.

The maintenance planning process is vital for prioritizing tasks that contribute to equipment longevity. A thorough assessment of equipment condition informs schedules maintenance activities and helps determine the appropriate intervals for maintenance tasks. By committing to a robust maintenance schedule, organizations can mitigate risks associated with wear and tear. As a result, equipment remains operational for a longer period, leading to enhanced productivity and reduced replacement costs.

Reducing Unplanned Downtime

A well-structured maintenance schedule is essential for minimizing unplanned downtime in any industrial setting. By implementing industrial maintenance scheduling practices, companies can establish a routine of scheduled maintenance that anticipates equipment needs and prevents sudden failures. The maintenance process becomes predictable with an auto-generated maintenance schedule, enabling teams to manage their maintenance operations efficiently. Emphasizing maintenance schedule benefits helps organizations maintain a focus on performance and reliability.

Creating a free maintenance schedule that is both effective and flexible allows for better adaptation to changing operational demands. With a well-organized maintenance schedule, facilities can prioritize essential tasks while ensuring that all equipment is adequately serviced. This proactive approach not only enhances productivity but also extends the lifespan of machinery, leading to substantial savings for the organization. Through effective industrial maintenance scheduling, businesses can significantly reduce the risk of unexpected downtime, ensuring smooth operations at all times.

| Maintenance Task | Frequency | Estimated Downtime Reduction |

|---|---|---|

| Monthly Equipment Inspections | Once a month | 25% |

| Quarterly Lubrication & Cleaning | Every three months | 15% |

| Annual Major Overhaul | Once a year | 50% |

| Daily Routine Checks | Every day | 10% |

Streamlining Maintenance Planning

Effective industrial maintenance scheduling is essential for successful maintenance operations in any organization. By employing dynamic maintenance planning, companies can create a scheduled maintenance program that aligns with their operational needs. This integration allows for a more streamlined approach to maintenance planning, ensuring that all tasks are prioritized and assigned appropriately. A well-structured vehicle maintenance schedule can serve as an example of how meticulous planning can enhance overall efficiency and productivity.

Implementing a robust maintenance management system can significantly reduce maintenance time and optimize operational scheduling. By leveraging data-driven insights, teams can adapt their industrial maintenance scheduling to respond to changing conditions and workloads. The aim is to ensure that maintenance activities, whether preventive or corrective, are efficiently organized. This holistic approach will facilitate smoother operations and foster a culture of proactive maintenance within the organization.

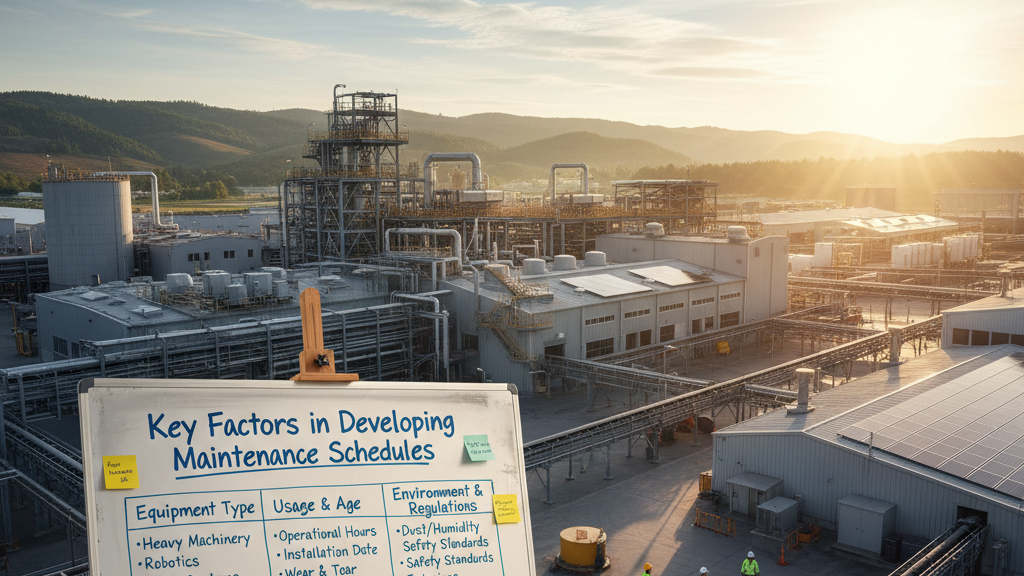

Key Factors in Developing Maintenance Schedules

Developing an effective industrial maintenance scheduling process requires careful consideration of various key factors. Assessing equipment condition helps ensure that an optimal maintenance plan is established, addressing the specific needs of different machinery. Defining maintenance frequency is crucial in determining how often certain maintenance work should occur to prevent breakdowns. Prioritizing maintenance tasks enables maintenance management to allocate resources efficiently and focus on the most critical operations first. By integrating maintenance management solutions, organizations can streamline their maintenance program and enhance the overall effectiveness of their maintenance work, ultimately leading to improved performance and reduced downtime.

- Regularly review and update maintenance schedules based on equipment performance data

- Involve maintenance staff in schedule development to gain practical insights

- Consider seasonal factors that may impact equipment usage and wear

- Utilize predictive maintenance technologies to anticipate failures before they occur

- Monitor compliance with maintenance schedules to identify areas for improvement

- Allocate budget resources effectively to ensure sufficient funding for maintenance activities

- Train staff continuously to keep them updated on best practices in maintenance management

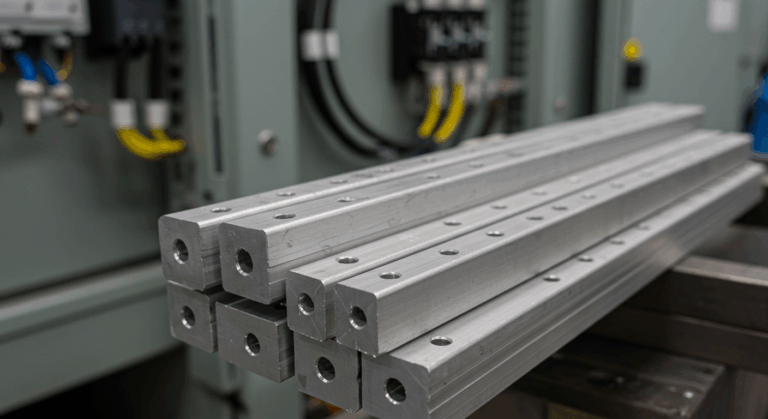

Assessing Equipment Condition

A thorough evaluation of equipment condition is essential for effective industrial maintenance scheduling. This assessment helps determine the appropriate timing for specific maintenance tasks within a preventive maintenance schedule. By creating a robust routine maintenance plan, organizations can identify which machinery requires attention and when to address those needs. Utilizing a maintenance schedule template can streamline this process, ensuring that all required monthly maintenance tasks are accounted for and executed efficiently.

Understanding the condition of equipment allows companies to prioritize different maintenance tasks effectively. Regular assessments inform maintenance teams about the current performance and health of machinery, enabling them to schedule routine maintenance and corrective actions as necessary. By focusing on a structured maintenance schedule, organizations can allocate resources more effectively, minimizing downtime and enhancing overall productivity through timely intervention on maintenance tasks.

Defining Maintenance Frequency

A crucial aspect of industrial maintenance scheduling lies in defining maintenance frequency. Establishing how often routine maintenance tasks should be performed helps create effective maintenance plans. A well-defined maintenance strategy integrates various elements, including equipment usage patterns and manufacturer guidelines, to optimize maintenance timelines. By utilizing maintenance scheduler apps, operators can streamline the typical scheduling process, ensuring that all necessary tasks are completed on time.

Successful maintenance planning requires a clear understanding of equipment life cycles and potential failure points. This information aids in developing a maintenance plan that balances preventive and corrective actions. By specifying maintenance frequency, industrial maintenance scheduling becomes more effective, resulting in minimized disruptions and enhanced operational efficiency. Implementing a thoughtful maintenance strategy allows organizations to proactively address equipment needs while maximizing productivity.

Prioritizing Maintenance Tasks

Effective maintenance planning relies heavily on prioritizing maintenance tasks. Industrial maintenance scheduling involves identifying critical maintenance tasks that directly impact equipment reliability and operational efficiency. A well-defined prioritization process helps organizations focus their resources on necessary maintenance tasks, ensuring that the most urgent issues are addressed promptly. Utilizing a maintenance optimization approach allows teams to assess the urgency and importance of specific maintenance tasks based on factors such as equipment failure history and operational impact.

Operational scheduling decisions should consider the overall maintenance strategy and the long-term goals of the organization. Balancing routine scheduling tasks with urgent repairs requires a clear understanding of maintenance priorities. By employing an effective maintenance planning framework, companies can streamline their industrial maintenance scheduling processes. This not only improves equipment performance but also enhances overall productivity and operational outcomes.

Maintenance Scheduling Software

Effective tools for industrial maintenance scheduling are crucial in managing a successful industrial preventive maintenance plan. These software solutions allow maintenance departments to efficiently track maintenance task status, ensuring proper oversight of routine scheduling and maintenance duration. By integrating features that accommodate additional maintenance work, they help streamline processes while addressing maintenance challenges. Such systems enable teams to proactively manage equipment maintenance, optimizing resources and minimizing downtime. Ultimately, these tools are vital for enhancing the overall effectiveness of an industrial maintenance scheduling strategy.

Features of Effective Maintenance Scheduling Software

Effective maintenance scheduling software plays a crucial role in industrial maintenance scheduling. It enables maintenance managers to make informed maintenance planning decisions, ensuring the right maintenance work is prioritized. Features such as real-time tracking of equipment conditions and automated reminders for upcoming maintenance tasks streamline workflows. A well-designed software solution supports maintenance planners in executing maintenance activities efficiently, reducing the likelihood of downtime and operational disruptions.

The integration of advanced analytics into maintenance scheduling software allows for the development of new maintenance strategies that adapt to evolving operational needs. This capability empowers maintenance managers to monitor performance trends and make necessary adjustments to the schedule. By providing insights into equipment performance, the software helps identify the appropriate time for maintenance actions, facilitating a proactive approach to industrial maintenance scheduling.

Popular Maintenance Scheduling Tools

Effective industrial maintenance scheduling relies heavily on the right tools. Maintenance management software systems are crucial for developing a good maintenance plan that can address intricate scheduling problems. These tools enable experienced maintenance planners to create a solid maintenance plan, integrating features like computerized maintenance management that helps streamline operations. By using these advanced scheduling practices today, organizations can significantly enhance their maintenance workflows.

A variety of maintenance scheduling tools are available in the market, each offering unique functionalities tailored to different needs. These tools often provide features for total maintenance management, ensuring that all aspects of industrial maintenance scheduling are efficiently covered. By leveraging technology, businesses can not only simplify their scheduling processes but also increase the effectiveness of their overall maintenance strategy. This results in better resource allocation and ultimately contributes to prolonged equipment lifespan.

How to Integrate Software into Existing Processes

Integrating software into existing processes requires a clear understanding of your industrial maintenance scheduling needs. Establish an initial maintenance plan that outlines current practices and how software can enhance them. A maintenance manager should assess the current state of maintenance efficiency and identify opportunities for improvement. Proper scheduling through software can lead to better maintenance resource utilization, ensuring that team members focus on the highest priority tasks.

Adopting software solutions involves developing key strategies and techniques for optimizing maintenance planning and adapting maintenance strategies to fit new tools. Training staff on the software’s functionalities is crucial to minimize resistance and maximize acceptance. With effective implementation, outcome-based maintenance planning becomes achievable, allowing organizations to improve overall performance and extend equipment lifespans.

Strategies for Creating an Effective Maintenance Schedule

Creating an effective maintenance strategy requires a thorough understanding of industrial maintenance scheduling and the specific needs of the maintenance department. It involves making daily scheduling decisions that prioritize necessary maintenance activities, ensuring that all industrial machines operate at peak performance. By developing clear maintenance policies, teams can establish criteria for efficient scheduling, balancing the workload while addressing urgent tasks. An effective maintenance strategy integrates proactive planning for both preventive and corrective maintenance, allowing for flexibility in adapting schedule adjustments based on operational demands and emerging trends in equipment performance.

Setting Priorities for Maintenance Activities

Effective industrial maintenance scheduling relies heavily on setting clear priorities for maintenance activities. By identifying and categorizing tasks into heavy maintenance and regular maintenance, organizations can ensure that technician schedules align with the maintenance needs of equipment. Specific maintenance activities must be prioritized based on their urgency and potential impact on productivity. An optimization-powered scheduling system can facilitate this prioritization, helping to streamline operations and minimize disruptions.

Maintenance records play a crucial role in developing an effective scheduling strategy. They provide valuable insights into past maintenance activities and equipment performance, allowing teams to forecast future needs. Prioritizing tasks based on historical data ensures that critical repairs and maintenance are addressed promptly, ultimately contributing to a long-term maintenance shop’s efficiency. This systematic approach enhances overall productivity and supports the objectives of industrial maintenance scheduling.

Monitoring Performance and Trends

Evaluating performance and trends within industrial maintenance scheduling is integral for achieving effective maintenance. Analyzing data related to industrial equipment helps identify patterns that inform maintenance needs. By understanding how the maintenance process unfolds, organizations can make informed decisions regarding resource allocation and timing. This proactive approach leads to a custom-fit maintenance planning strategy that maximizes efficiency and extends the life of assets.

Regular monitoring enables maintenance technicians and experienced maintenance providers to fine-tune their practices based on real-time insights. Adjusting schedules based on performance metrics not only enhances overall maintenance but also ensures that maintenance interventions are timely and relevant. Keeping a close eye on trends allows teams to anticipate potential failures and address them before they escalate, ensuring that industrial maintenance scheduling remains both effective and adaptive.

Adapting Schedules Based on Operational Needs

Flexibility in industrial maintenance scheduling is essential for addressing varying maintenance objectives across different equipment and operations. Maintenance software can streamline this adaptability, allowing maintenance personnel to adjust schedules based on real-time data. By analyzing maintenance history and monitoring equipment performance, organizations can create tailored maintenance strategies that align with current operational needs. This proactive approach ensures that maintenance actions are both timely and relevant, ultimately reducing disruptions and enhancing overall productivity.

Effective maintenance planning avoids common pitfalls such as over-scheduling or neglecting critical tasks. By continually assessing maintenance frequency requirements, businesses can fine-tune their schedules to reflect the dynamic nature of their operations. Incorporating insights from maintenance software into decision-making processes allows for a responsive scheduling framework, ensuring that maintenance personnel can prioritize tasks effectively. This adaptability not only improves the efficiency of maintenance activities but also contributes to a more resilient operational environment.

Challenges in Maintenance Scheduling

Balancing preventive and corrective maintenance poses a significant challenge for industrial maintenance scheduling. Industrial facilities often rely on a dedicated maintenance workforce to manage various maintenance functions, making it essential to establish a strong maintenance connection between scheduled tasks and real-time operational needs. Frequent maintenance activities can lead to disruptions in industrial operations if not carefully managed. A work order scheduler is critical in this process, ensuring that both preventive measures and corrective adjustments are prioritized effectively. This balance ultimately contributes to the overall efficiency of the industrial facility and the longevity of its equipment.

| Challenge | Description | Impact on Operations |

|---|---|---|

| Balancing Maintenance Types | Finding the right mix between preventive and corrective maintenance. | Increases equipment uptime but risks operational disruptions if not managed well. |

| Resource Allocation | Ensuring enough staff and resources are available for scheduled and unscheduled tasks. | Potential delays in maintenance, affecting productivity and equipment reliability. |

| Real-time Adjustments | Adapting maintenance schedules based on actual operational conditions. | Increased responsiveness but requires effective communication and scheduling systems. |

| Data Management | Effectively tracking maintenance records and operational data. | Inaccurate data can lead to inefficiencies and missed maintenance opportunities. |

Balancing Preventive and Corrective Maintenance

Effective industrial maintenance scheduling requires a careful balance between preventive and corrective maintenance strategies. A predictive maintenance approach enables maintenance teams to identify potential failures before they occur, minimizing unplanned downtime and optimizing the maintenance period. By focusing on right maintenance practices, organizations can ensure that maintenance connection today aligns with both operational needs and regulatory maintenance requirements.

Allocating resources appropriately within a maintenance program is essential for achieving productive maintenance essentials. Maintenance teams must prioritize tasks based on equipment criticality and operational impact. This approach allows for efficient scheduling that meets both preventative and corrective maintenance goals, ensuring that the industrial maintenance scheduling process remains agile and responsive to changing conditions in the facility.

Conclusion

Industrial maintenance scheduling is essential for ensuring the optimal performance of machinery and equipment in various sectors. A well-structured preventive maintenance schedule enhances operational efficiency and minimizes the risk of unexpected failures. Companies can organize different maintenance tasks using a standard maintenance schedule template, which allows for the clear allocation of specific maintenance tasks. Regular monthly maintenance tasks can be seamlessly integrated into a routine maintenance plan, creating a proactive approach to equipment care. Balancing preventive measures with necessary corrective actions ensures that all maintenance tasks are prioritized effectively, ultimately leading to improved reliability and longevity of industrial operations.

FAQS

How can I create an effective maintenance schedule for scheduled maintenance in my factory?

To create an effective maintenance schedule for scheduled maintenance programs in your factory, it’s essential to first assess the current state of your machinery and equipment. Implementing an industrial preventive maintenance plan allows you to proactively address potential issues. Ensure that your maintenance departments plan includes a detailed outline of maintenance activities and their frequency. Utilize software tools to help manage your schedule maintenance efficiently, allowing for adjustments as needed. By continuously evaluating and adapting maintenance strategies, you can optimize your maintenance schedule and execute maintenance activities promptly, ensuring that your factory runs smoothly.

What factors should I consider when developing a maintenance schedule for effective maintenance in an industrial setting?

When developing a maintenance schedule, it is crucial to ensure that your maintenance schedule isn’t just a routine but rather a well-structured scheduled maintenance program. This includes creating an industrial preventive maintenance plan that highlights the most efficient maintenance activities. By continually evaluating and adapting maintenance strategies, you can ensure that your maintenance program meets the operational needs of your facility.

What are the best practices for developing a maintenance schedule for maintenance in an industrial environment?

To create an effective maintenance schedule, consider implementing a scheduled maintenance program that includes an industrial preventive maintenance plan. It’s essential to adapt maintenance strategies based on the type of equipment, frequency of maintenance activities, and the overall maintenance program you are using. Proper planning and scheduling can significantly improve equipment reliability and operational efficiency.

How do I optimize my maintenance schedule for maintenance tasks to improve factory operations?

To optimize your maintenance schedule, consider implementing a structured scheduled maintenance program alongside an industrial preventive maintenance plan. This ensures that each maintenance activity is timed effectively to minimize downtime and maximize efficiency within your maintenance program.

How can I ensure my maintenance schedule for maintenance aligns with a scheduled maintenance program in an industrial facility?

To ensure your maintenance schedule for maintenance aligns with a scheduled maintenance program, you should develop a comprehensive industrial preventive maintenance plan that outlines all necessary tasks, frequencies, and resources. Regularly review and adjust your maintenance program based on equipment performance and operational needs to enhance efficiency and reliability.

How can I enhance my maintenance schedule for maintenance tasks to effectively implement a scheduled maintenance program in my industrial facility?

To enhance your maintenance schedule for maintenance tasks, focus on developing a robust scheduled maintenance program that includes routine checks, detailed logs, and a proactive approach to industrial preventive maintenance plans. This will streamline your operations and ensure that your maintenance program is efficient and effective in minimizing downtime.

What steps can I take to improve my maintenance schedule for maintenance in an industrial facility?

To enhance your maintenance schedule for maintenance, consider integrating a scheduled maintenance program that includes a comprehensive industrial preventive maintenance plan. A well-structured maintenance program is crucial for ensuring optimal performance and reducing downtime in your facility.

How can I modify my maintenance schedule for maintenance tasks to better support a scheduled maintenance program in my industrial facility?

To modify your maintenance schedule for maintenance tasks effectively, begin by evaluating your current scheduled maintenance program. Ensure that it incorporates elements of your industrial preventive maintenance plan to enhance efficiency. Additionally, gather data on equipment performance and failure rates to inform adjustments to your maintenance program, allowing for more proactive scheduling that minimizes downtime and maximizes productivity.

How can I improve my maintenance schedule for maintenance to support a comprehensive preventive maintenance plan in my industrial setting?

To improve your maintenance schedule for maintenance, start by reviewing your current scheduled maintenance program to identify any gaps or areas for enhancement. Incorporate a preventive maintenance plan that focuses on routine tasks, timely inspections, and predictive analysis to minimize downtime and extend equipment life. Additionally, ensure that your maintenance program includes regular assessments to refine and adapt the schedule based on operational demands and historical data.

How can I develop a maintenance schedule that effectively incorporates both maintenance tasks and a scheduled maintenance program in an industrial facility?

To develop a maintenance schedule that integrates maintenance tasks with a scheduled maintenance program, you should first assess the existing industrial preventive maintenance plan. This includes evaluating equipment needs, identifying critical maintenance tasks, and timing them to align with your maintenance program. By systematically planning and prioritizing tasks, you can ensure that all scheduled maintenance activities are effectively implemented within the maintenance schedule, enhancing overall operational efficiency in your industrial setting.